"Urambo Tauro" (urambotauro)

"Urambo Tauro" (urambotauro)

03/21/2019 at 20:30 ē Filed to: rustventures, anti-seize, wrenching

3

3

26

26

"Urambo Tauro" (urambotauro)

"Urambo Tauro" (urambotauro)

03/21/2019 at 20:30 ē Filed to: rustventures, anti-seize, wrenching |  3 3

|  26 26 |

So Future Heap Ownerís recent !!!error: Indecipherable SUB-paragraph formatting!!! has me reconsidering the use of anti-seize on lug nuts...

!!! UNKNOWN CONTENT TYPE !!!

We touched on this subject earlier when I shared John Cadoganís lengthy !!!error: Indecipherable SUB-paragraph formatting!!! on the matter. To sum up, he reasoned that thereís a wide safety margin of safe torque, that the use of thread and/or seat lubricant doesnít screw up torque readings enough to worry about, and that the important thing we should be focusing on anyway is using a torque wrench instead of going crazy with the rattle-gun.

Now FWIW, despite living in a salt state, my habit thus far has been not to use anti-seize on lugs. Sometimes I do see it already applied to a car, but I donít bother to clean it off because I appreciate the assurance that the threads wonít be locked up. But somehow Iíve been getting along just fine without it myself...

I was thinking that maybe the deciding factor was going to be the use of capped lug nuts (or hub caps that completely cover the lugs from the elements), but the pictures in FHOís post are making me doubt that. I mean, those studs are definitely rusty, right where the nuts go, and the capped nuts didnít seem to help prevent that.

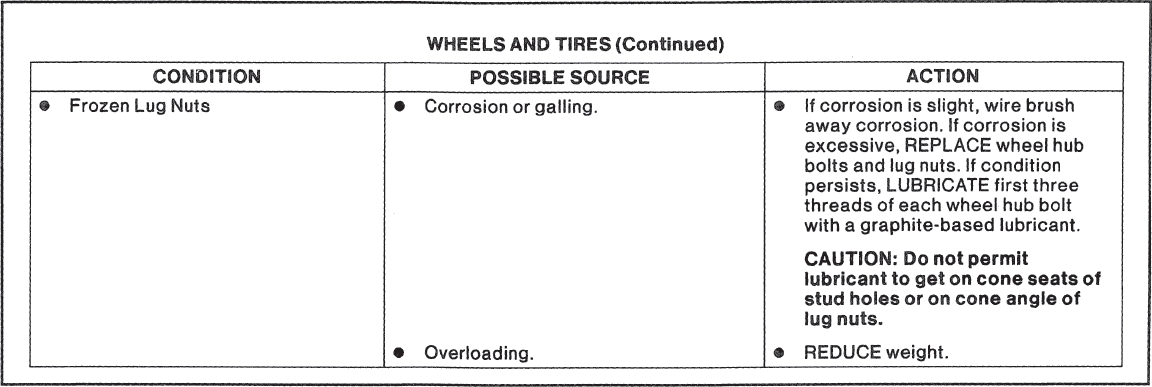

T he fear that the lubrication will make it too easy to overtorque the lugs is perhaps the most popular concern when it comes to using anti-seize here. And many service manuals come with explicit warnings against lubricating lugs. My Sierra manual states the following:

Notice: A torque wrench... must be used to ensure that wheel nuts are tightened to specification. Never use lubricants or penetrating fluids on wheel stud, nuts, or mounting surfaces, as this can raise the actual torque on the nut with out a corresponding torque reading on the torque wrench. Wheel nuts, studs, and mounting surfaces must be clean and dry.

Hm. I hope that the ďmounting surfacesĒ are a reference to the fastener seats, because I canít imagine lubricating the face of the hub or backside of the wheel would be problematic. In fact, my Mustangís service manualís warnings are phrased a bit differently, recognizing the need for preventative measures against rust:

Corrosion buildup can result in wheels sticking to the axle or rotor flange after extensive service...

Coat wheel pilot area with Disc Brake Caliper Slide Grease... or equivalent meeting Ford specification... Do not apply grease to lug nut seats or wheel hub bolts.

Hereís the kicker, though. While Ford does say not to use ďgreaseĒ (which might be a specific reference to the aforementioned ď Disc Brake Caliper Slide Grease Ē) on the threads, they do apparently permit careful use of a ďgraphite-based lubricantĒ:

It seems to me that lubricating only the first three threads allows the nut to carry only a very small amount of lubricant to the nutís final position. So little in fact, that Fordís recommended lug torque spec of 85-105 lb-ft is left unchanged.

So it would seem that lubricating lugs can be an acceptable practice after all, depending on the type of lubricant used, and the technique of application. There might even be a proper way to use regular anti-sneeze, despite manufacturer warnings. Maybe they just didnít bother taking the time to study a safe method of using it, to include in the manual.

Now that I actually take the time to google it, !!!error: Indecipherable SUB-paragraph formatting!!! claims that you should undertorque a lubricated faster by 30%; 40% if using SAE 30 oil. As for anti-seize in particular, !!!error: Indecipherable SUB-paragraph formatting!!! from AST Industries advises that when using their product, you should aim for an undertorque of 25%. Curiously, Permtexís !!!error: Indecipherable SUB-paragraph formatting!!! states to ďreassemble parts using normal torque valuesĒ, implying that their ďrefined blend of aluminum, copper and graphiteĒ has a negligible effect on torquing.

This may reflect an inconsistency in their testing methods. Or perhaps weíre comparing apples to oranges formula-wise. How deep does this rabbit hole go?

Future Heap Owner

> Urambo Tauro

Future Heap Owner

> Urambo Tauro

03/21/2019 at 20:51 |

|

I tís had me rethinking it as well! After finally getting the wheels off , I sprayed more WD-40 brand rust penetrant on the studs and let it soak for a few minutes, then cleaned them off with a rag, though not too thoroughly . Because of your earlier post on this subject , it didnít seem too crazy to have some left on there.

Iím planning to get new tires in the next few weeks, so the wheels will come off again for that. Then the real test will be when I next rotate them, likely in six months. If theyíre all rusted up again, Iím gonna do a real thorough cleaning of the studs and then lube the nuts/studs when I put them back on.

I do think youíre right that manufacturers are likely to be conservative on this. Thereís no real incentive for them to test it out; easier to just say ď donít do itĒ as a CYA measure.

WildlyMild

> Urambo Tauro

WildlyMild

> Urambo Tauro

03/21/2019 at 21:01 |

|

Maybe the autotrader manufacturers should put that on at the factory because....... Nope, teams of 40 hour a week application specific engineers with 100 years of history have determined †that its not a good idea. Rotate regularly and replace your studs and nuts if you're overly concerned.

functionoverfashion

> Urambo Tauro

functionoverfashion

> Urambo Tauro

03/21/2019 at 21:03 |

|

I donít lubricate the bolts/nuts, but I do use a product on the surface of the rotor where the wheel makes contact with it.

What I use is a marine product that I use for all kinds of things, I think itís called Special Lubricant 101 (Quiksilver brand, aka Mercury). Itís used for assembling lower unit parts on an outboard and is highly resistant to moisture. It has the consistency of toothpaste, so I spread a bit on with my finger, then when I put the wheel on I spin it a bit to spread it more evenly. A little teeny bit gets into the holes for the bolts, so I guess thatís something. But itís very, very little.

I never have trouble getting my wheels off, but then I also change them out every 6 months or so - winter to summer.

Thatís my 2 cents. Something to keep the hub and rotor from rusting together = fine. And if the wheels arenít left on for 2 years straight, the bolts / nuts should come off fine with little to no product added, and proper torque.†

Decay buys too many beaters

> Urambo Tauro

Decay buys too many beaters

> Urambo Tauro

03/21/2019 at 21:16 |

|

Have been using this for a while now on just about every large fastener that doesnít call out grease and potentially gets moisture exposure. Been great so far.

*note, itís usually a lot cheaper. Not sure why itís so expensive on amazon right now

Spamfeller Loves Nazi Clicks

> Urambo Tauro

Spamfeller Loves Nazi Clicks

> Urambo Tauro

03/21/2019 at 21:17 |

|

Iím going to say this once. Very loudly.

DO NOT FUCKING APPLY ANTI-SEIZE OR ANY LUBRICANT TO LUG NUTS OR WHEEL STUDS UNLESS YOU HAVE A PORSCHE WITH CENTERLOCKS!!

Wait. I donít think people have gotten the message yet.

DO NOT FUCKING APPLY ANTI-SEIZE OR ANY LUBRICANT TO LUG NUTS OR WHEEL STUDS UNLESS YOU HAVE A PORSCHE WITH CENTERLOCKS!!

Hmm. Some people are still asking the question.

DO NOT FUCKING APPLY ANTI-SEIZE OR ANY LUBRICANT † TO LUG NUTS OR WHEEL STUDS UNLESS YOU HAVE A PORSCHE WITH CENTERLOCKS!!

NO, THAT GUY YOU HEARD SUCH AND SUCH FROM, WHO GOT IT FROM THIS FORUM, THAT GOT IT FROM SOME ĎOLD SCHOOLí MECHANIC IS NOT CORRECT AND NEVER HAS BEEN!!

DO NOT FUCKING PUT ANTI-SEIZE ON LUGS . There is a REASON the owners manual says it, there is a REASON the FSM says it a dozen plus times. Anti-seize WILL PREVENT PROPER TORQUING.

Know how many threads you apply Loctite to? 1 to 3. BECAUSE IT MIGRATES WHEN YOU TORQUE DOWN THE BOLT. The pressure squeezes it right up the rest of the threads! This is TESTED stuff, this is KNOWN stuff. Lubricants WILL migrate, and in load applications, they WILL cause backing out.

Use a wire brush cylinder or equivalent to clean corrosion off wheel studs, replace lug nuts when mating faces are significantly corroded. Go absolutely hog wild with penetrant if thereís lots of rust. Sandblast the damn things if you want.

But DONíT PUT LUBRICANTS ON LUGS.

Decay buys too many beaters

> Spamfeller Loves Nazi Clicks

Decay buys too many beaters

> Spamfeller Loves Nazi Clicks

03/21/2019 at 21:30 |

|

Counterpoint, anti seize your lugnuts.

just-a-scratch

> Decay buys too many beaters

just-a-scratch

> Decay buys too many beaters

03/21/2019 at 22:00 |

|

No. Please do not.

atfsgeoff

> Spamfeller Loves Nazi Clicks

atfsgeoff

> Spamfeller Loves Nazi Clicks

03/21/2019 at 22:06 |

|

The best way to prevent stuck lug nuts is to place a latex condom over each stud before running the nut down and torquing to spec, everyone knows this

Just make sure NOT to use lubricated condoms

AMGtech - now with more recalls!

> Urambo Tauro

AMGtech - now with more recalls!

> Urambo Tauro

03/21/2019 at 22:15 |

|

Donít do it. If you're worried about it all seizing together, rotate your tires more often.

BigBlock440

> Spamfeller Loves Nazi Clicks

BigBlock440

> Spamfeller Loves Nazi Clicks

03/21/2019 at 22:17 |

|

Meh, Iíve literally never had a problem with anti-seize

on lugnuts, and WD40 helps them come off if theyíre the open type. I have broken breaker bars from dry nuts, as recently as a month ago. Just this past Saturday I finished the longest tire rotation ever because the previous owner didnít put anti-seize

on

anything

and the wheels were seized

to the rotors.

Pixel

> Urambo Tauro

Pixel

> Urambo Tauro

03/21/2019 at 22:18 |

|

E ntirely anecdotal evidence, but I have used anti-seize on the rotor face and lugs for decades, and have never had a loose lug-nut situation that could remotely be related to it[1].

I have spent way too much time fighting with lug nuts and hammering wheels off hubs on vehicles that hadnít had anti-seize used. I also use a skim coat on hubs before I install rotors to keep those from rusting in place as well.

[1] Fit wheels have needed regula r r etorquing, but those are Toyota ste elies with the center bores ground out to fit the wider Honda hubs.

Spamfeller Loves Nazi Clicks

> BigBlock440

Spamfeller Loves Nazi Clicks

> BigBlock440

03/21/2019 at 22:35 |

|

Wheels seize to rotors and hubs because lazy mechanics donít clean off the mating faces when doing rotations. So the materials literally rust together. This does not occur because there isnít anti-seize on the studs. Has nothing to do with lugs and studs.

I live in the permanent rust-belt. Never had a single seized lug nut from rust; always over-torquing by idiots or corroding to the mating face . And one big ass sledge for busting wheels off the rotors.

shop-teacher

> Urambo Tauro

shop-teacher

> Urambo Tauro

03/21/2019 at 22:44 |

|

I've never had this problem, and I wonder if it's because my wheels come off 2 times a year at least. I'm sure some people's wheels never come off between getting new tires or brake jobs, and that could be years.†

BigBlock440

> Spamfeller Loves Nazi Clicks

BigBlock440

> Spamfeller Loves Nazi Clicks

03/21/2019 at 23:00 |

|

I live in the permanent rust-belt. Never had a single seized lug nut

from rust; always over-torquing by idiots or corroding to the mating

face. And one big ass sledge for busting wheels off the rotors.

An 8 lb wasnít enough, I doubt a 20 lb would have done anything other than knock the car off the jack stands. I ended up having to use a puller.

But thatís great that you never had one seize due to rust, and maybe mine was seized

due to over torquing

and rust combination, but either way, antiseize would have made it easier to remove without breaking a 1/2" bar

.

I shouldnít have to use a 3/4" socket set

to ensure I donít break it working on a

car

. And while I donít think the rust belt extends much farther east than Pittsburgh, thatís irrelevant to how much rust forms on a vehicle. Ironically, rust belt cars probably have less rust than cars outside of it.

Rusty Vandura - www.tinyurl.com/keepoppo

> AMGtech - now with more recalls!

Rusty Vandura - www.tinyurl.com/keepoppo

> AMGtech - now with more recalls!

03/21/2019 at 23:21 |

|

Yaí canít talk religion with some people.

Alfalfa

> Spamfeller Loves Nazi Clicks

Alfalfa

> Spamfeller Loves Nazi Clicks

03/21/2019 at 23:21 |

|

Rusty Vandura - www.tinyurl.com/keepoppo

> BigBlock440

Rusty Vandura - www.tinyurl.com/keepoppo

> BigBlock440

03/21/2019 at 23:25 |

|

Iíve been using copper paste for like 30 years. I donít use a torque wrench, either. Nice and good and snug, and evenly torqued. I also rotate my tires

diligently

every 5,000 miles on the clock. And inspect the brakes and all of that jazz. The guy who got me started doing that had seen his father do it for decades prior to that. So Iím with you. Root Wyrm and AMG are guys who know their s**t, but I am choosing not to take their advice on this one.

Rusty Vandura - www.tinyurl.com/keepoppo

> Spamfeller Loves Nazi Clicks

Rusty Vandura - www.tinyurl.com/keepoppo

> Spamfeller Loves Nazi Clicks

03/21/2019 at 23:27 |

|

Iím sorry you did not think you could tell us how you really fee

l about this. The guy who got me started with this practice 30 years ago had me use copper paste, and said basically the opposite of what you are saying. But hey: yaí just canít talk religion with some people.

M.T. Blake

> Urambo Tauro

M.T. Blake

> Urambo Tauro

03/21/2019 at 23:58 |

|

Please tell me someone said Neutrogena!†

oldmxer

> Urambo Tauro

oldmxer

> Urambo Tauro

03/22/2019 at 00:26 |

|

50 years experience in machine shop/mechanics, friction is a bigger factor in torque readings than most think. copper based anti seize applied sparingly is the only way to go in any situation I have experienced. if you use nothing you are never going to get proper torque on anything where specific torque values are critical. dry threads have wildly different coefficient of friction between the two metal surfaces of the male and female threads. i say threads because on lug nuts it is not a good idea to use any lube on the fit between the nut and the wheel. each manufacturer designs the lug nuts to fit the wheel surface where they are clean and dry. this surface is what keeps the nut from backing off during normal use, otherwise they can back off from normal forces of the dynamics of the interaction between acceleration, braking and cornering

gogmorgo - rowing gears in a Grand Cherokee

> Urambo Tauro

gogmorgo - rowing gears in a Grand Cherokee

> Urambo Tauro

03/22/2019 at 00:35 |

|

I fully disagree with lubrucating lug nuts, as I mentioned last time that dipshitís videos got shared . Rotate your tires on a regular schedule, and itís not going to be an issue. If your lug nut covers start swelling, which youíll notice if youíre rotating your tires regularly, get new lug nuts. I prefer to go for a matched set on each wheel myself, which means replacing all the nuts on the wheel. This will likely give you a few extra decent ones to move onto other wheels as well.

Graphite-based lubricants stay put. They dry on, providing a decent non-stick surface if you will. and donít really get pushed around much. Hitting the first three threads will make it easier to start the nut, which should always be hand started to ensure its not crossthreaded. Iíll spin them down with the impact wrench but only with a slight trigger pressure, and then torque them properly.

As I said before, torque specs arenít really about the studs. Itís about the clamping force and the conical seats. Overtorquing your wheels will damage them. It stretches out the lug holes, and with steel nuts on aluminum wheels, it can erode material from the wheel. This is one of the primary reasons to not exceed the torque spec, conical fastener interfaces put force outwards, not just down. Lubricated threads are also more likely to come loose on their own, especially if thereís lubricant on both the threads and face.

Wheel seats and mounting surfaces need to be clean because dirt, etc., will cause the wheel to sit off the mounting surface. This means your wheel maybe doesnít go on straight, and if the contaminants fall out while driving then you loose the clamping force from your lug nuts. Wheel mounting surfaces need to be dry because liquids can also act to lift the wheel off the seat, and they can easily lead to corrosion. This is part of why itís so critical to retorque the lug nuts. I will however use antiseize on the hub seat, because thatís where corrosion will give you trouble getting the wheel off. Lug nut threads are generally sealed in pretty nicely, but the hub caps on steel wheels especially donít seem to do much for keeping water away from the hole in the middle of the wheel, and beating wheels off with a hammer gets old in a hurry. Any excess antiseize gets squeezed out, and again, that retorque is happening too.

gogmorgo - rowing gears in a Grand Cherokee

> Future Heap Owner

gogmorgo - rowing gears in a Grand Cherokee

> Future Heap Owner

03/22/2019 at 00:45 |

|

Penetrating oil to clean, scrub with a wire brush, sure, then clean off with brake clean or similar.

I donít know where that Aussie dude gets his ideas, but if youíre rotating tires on the regular, thereís no way your lug nuts will rust to the lugs. It doesnít happen in the Canadian Rockies where road salt is key to highway survival and where the last snowfall of the winter is in June and the first of the next is in August, and it might still snow in July. Unless heís driving into the ocean on the regular, I donít know how heís managing to rust his lug nuts in place. He is however generating lots of views by taking a controversial position on a common piece of knowledge...

BigBlock440

> Rusty Vandura - www.tinyurl.com/keepoppo

BigBlock440

> Rusty Vandura - www.tinyurl.com/keepoppo

03/22/2019 at 10:47 |

|

It shouldnít be necessary if you rotate them every few months, but having multiple cars where 5k miles could take 2 years, and being in the north, Iíll keep doing it. Some cars I probably take the tires off enough to not worry about it, but others, especially my truck, I only put like 1K/year on, yeah those get anti- seize every time.

This car was new to me, so I have no idea how long those tires were on before I tried to take them off.† Iíll do what I can to avoid that scenario.

4kc

> Urambo Tauro

4kc

> Urambo Tauro

03/22/2019 at 10:58 |

|

I slap a glob o grease on the centering ring and pb blast the studs and wipe them off. Havenít had anything rust together yet...

Rusty Vandura - www.tinyurl.com/keepoppo

> BigBlock440

Rusty Vandura - www.tinyurl.com/keepoppo

> BigBlock440

03/22/2019 at 11:32 |

|

Iím no scientist nor engineer, but I donít think some anti-seize on the lug nuts, as long as you donít over-torque them, is going to hurt anything.

MM54

> Urambo Tauro

MM54

> Urambo Tauro

03/22/2019 at 19:39 |

|

I put regular silver anti-seize on the lugs of anything which will see salt, including on the face of the hub if itís an alloy wheel. Iíll torque to mid/low range of the spec. This includes on the threads and inevitably on the seat of the lug nut - it makes a huge difference come spring when you swap the summers back on, and [anecdotal evidence alert] Iíve never had an issue.